Consumer Goods AND Services Industry

When the nation's leading Greeting Card Company realized they were losing market share to mass retailers, they looked to R+L Global for an innovative, team-based solution to drive a nation-wide rollout.

CHALLENGE

Although the company had annual revenues of $9 billion and 20,000 domestic locations, they needed to respond quickly to competition by mass retailers who were attacking their market share. The solution was to roll out new product and merchandising formats in more than 4,000 locations as soon as possible. The challenge was compounded when the company realized the process would also require multiple vendors.

The major product needed for the roll out would come from one location, while the necessary merchandising fixtures and components would come from multiple vendors in several different locations. Careful timing and coordination were critical success factors.

As the project plan unfolded, the company identified still another potential danger – the marketing department was having difficulty closing the sale to convert the retailers to their product. The cost of downtime at each store, and the internal logistics required to complete the setup in a timely manner, could render the entire project ineffective and cost-prohibitive from the retailers’ perspective. To overcome the problem, all products and fixtures would need to arrive at the stores in "retail ready" format upon delivery, with minimal assembly and set-up on site. Downtime would have to be reduced from days to hours in order to receive commitment from the retailers to implement the plan. Assembly and set-up would also have to be completed upon delivery in order for the stores to be operational in time for the opening.

The company outlined three essential requirements:

- The entire operation would require a 98%+ reliability factor for on-time deliveries and with a lower tolerance for damage than is commonly associated with traditional shipping methods.

- Downtime at each store would be limited to 6 hours or less and a new system of assembly and set-up would be needed to complete the roll-out at each location.

- The company would need a transportation and logistics provider with a proven track record of innovative teamwork and collaboration.

SOLUTION

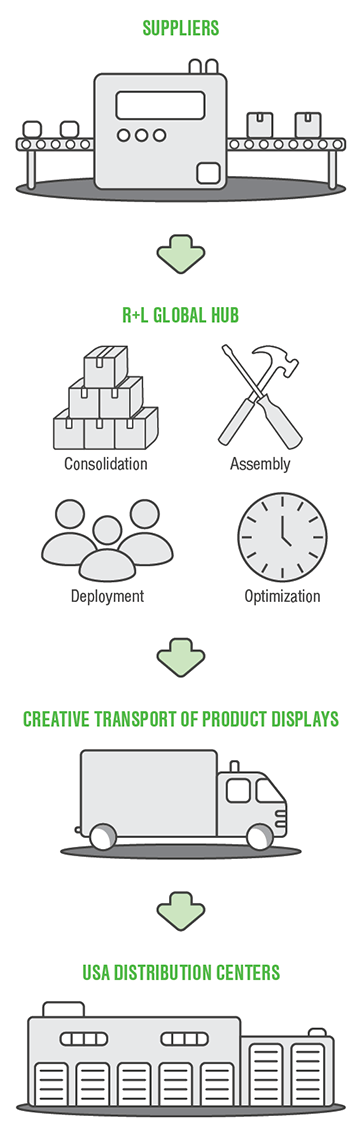

After outlining the project, the company turned to R+L Global Logistics for the best network and mode of transportation to support a flawless execution. R+L Global's response to the challenge involved a four-step process, which leveraged the use of a centralized hub for the warehousing and assembly of both the product and fixtures.

The first step was to develop a detailed production plan to carefully coordinate day and time-specific delivery schedules.

We worked closely with the customer to outline an effective schedule to address the timing and coordination requirements of each location and vendor.

Second, a system was developed to preassemble both the product and fixtures at the hub in a "retail ready" fashion. This step-by-step approach helped ensure safe delivery and timely set-up once the items arrived at the retailers’ locations.

We also worked with the customer to develop an automated load planning tool to handle any schedule changes and to identify the most efficient line-haul methods.

Finally, an eight-member installation team was selected, trained, and deployed to each store location. We worked closely with the customer to quickly assess the quality of all product and fixtures on delivery and completed the nationwide rollout.

RESULTS

Our collaborative approach to teamwork and innovation allowed the company to move their product to market in record time and maintain their competitive edge.

In the final analysis, the company confirmed 98.9% on-time and 99.999% damage-free delivery of all goods shipped. The average down time at each store was four hours and the change-overs and set-ups were seamless to the customer.

Teamwork and innovation are industry benchmarks used by R+L Global Logistics to consistently exceed customer expectations.